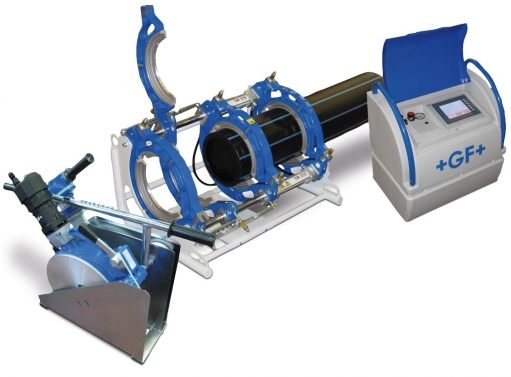

Electrofusion is a method of joining MDPE, HDPE and other plastic pipes using special fittings that have built-in electric heating elements which are used to weld the joint together.

The pipes to be joined are cleaned, inserted into the electrofusion fitting (with a temporary clamp if required) and a voltage (typically 40V) is applied for a fixed time depending on the fitting in use. The built in heater coils then melt the inside of the fitting and the outside of the pipe wall, which weld together producing a very strong homogeneous joint. The assembly is then left to cool for a specified time.

Main Benefits : - Leak free welded system

- Low investment start-up costs

- Modularity reduces stockkeeping

- Speed of installation

Main Applicatios : Gas and Water Distribution, Pressurised PE Piping Systems, Waste Water/Sewage, Cooling Systems

Product Range : 20mm to 630mm

Pressure Rating : Up to 16 bar for Water Distribution

Up to 10 bar for Gas Distribution

Benefits of Jointing Technology : Speed, flexibilty, one machine wleds all dimensions of fittings

Material : PE100; these fittings can aso be welded onto PE63 and PE80 Pipes